Assembling Your New Creality Printer

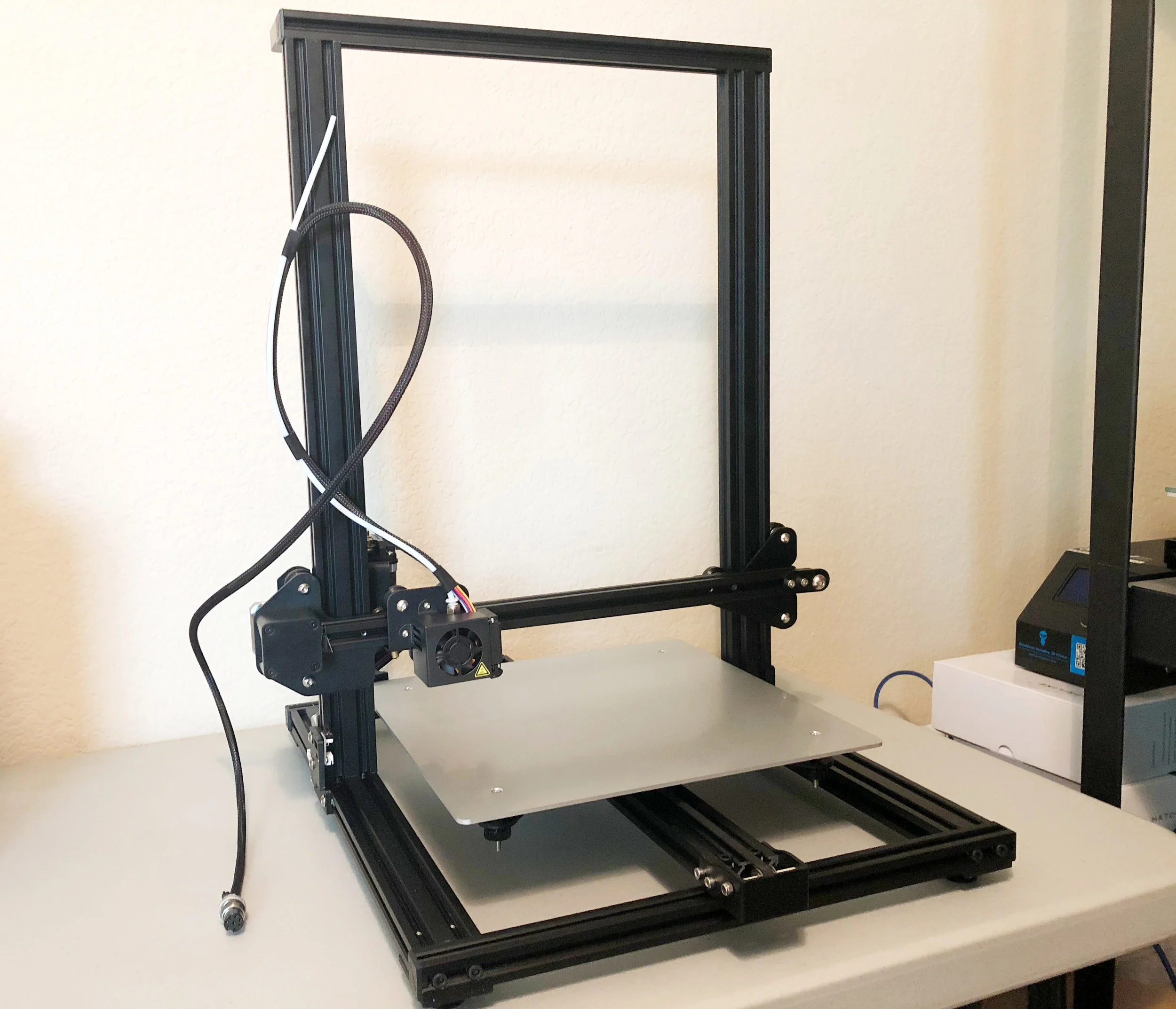

The Creality CR-10, CR-10 S4 and CR-10 S5 require a few assembly steps, but don't worry--it's very simple! The assembly process only takes around 15-30 minutes and is easy to do. We'll walk you through the process. The pictures in this guide are from a Creality CR-10, but the same process applies to the larger S4 and S5 printers as well.

Unboxing The Printer Base

Remove the printer base from the box

Remove the glass from the printer base

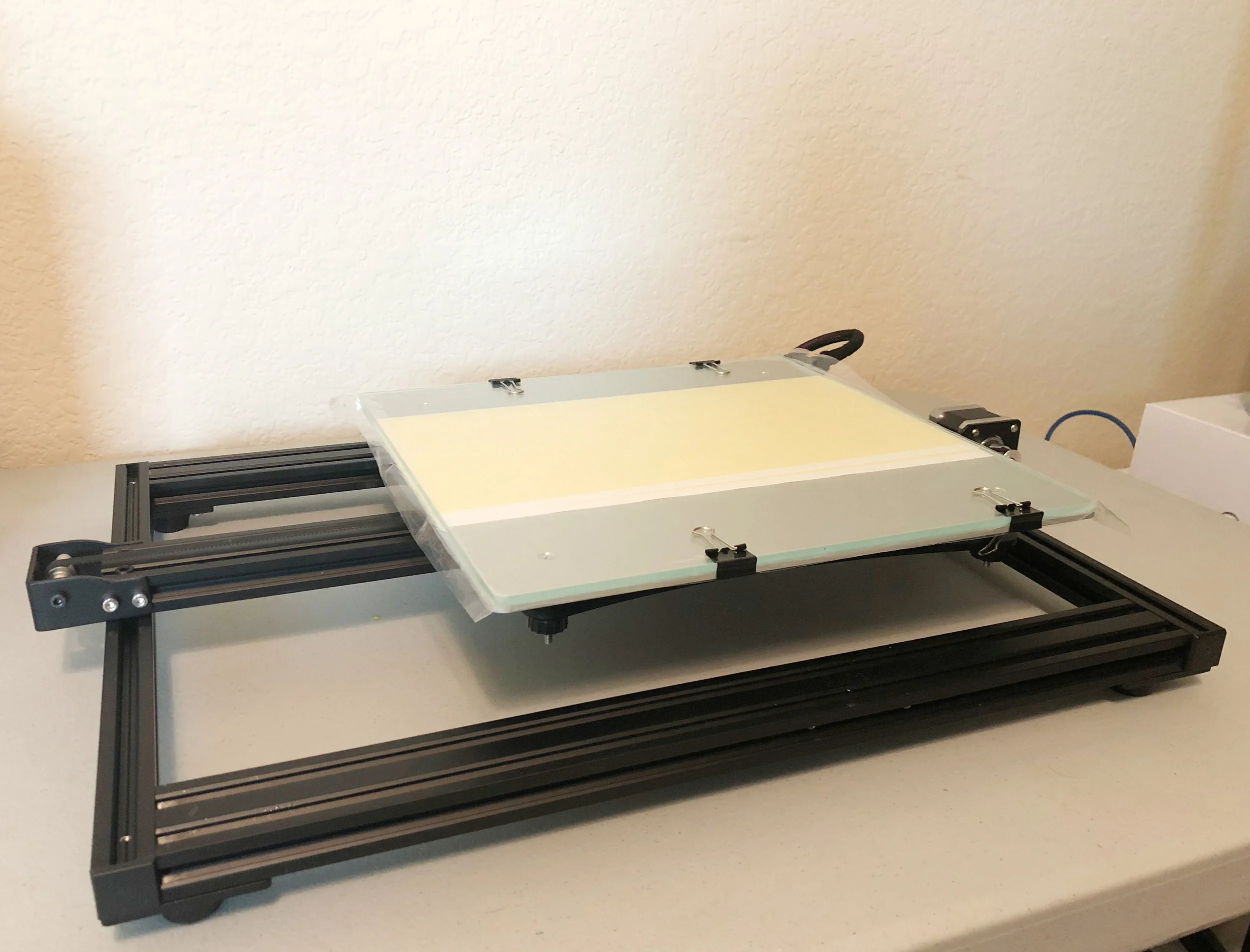

When you open the box for your new printer, you'll find the two main pieces of the printer packed in foam. The first part you see when you open the box is the base of the printer, so you can simply pull it out of the packaging and set it on the table. The print bed will be secured to the base with plastic wrap, which you should remove.

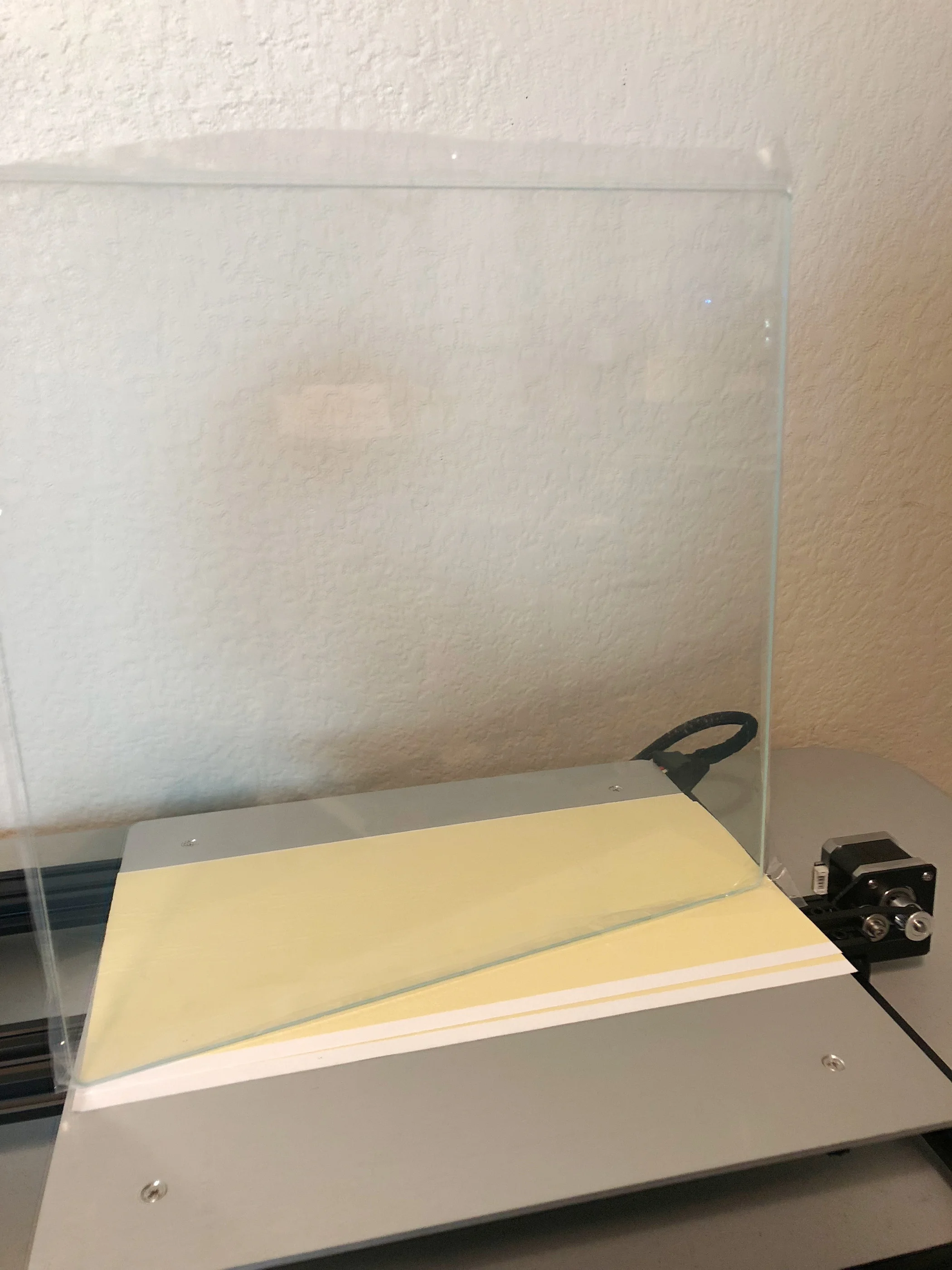

The glass on the print bed is secured to the bed with four binder clips. We recommend removing the glass for the rest of the setup process, so remove the binder clips and take the glass off of the print bed. Set it aside for now.

Creality includes a few pieces of sticky paper that is intended for use on the print bed, but we typically do not use the paper. You can discard it or set it aside to experiment with later. It's not necessary for the printer. We have found that applying a light coat of hairspray provides great print adhesion, and also allows parts to be removed easily once the bed is cooled. (we have had the best results with AquaNet Extra Super Hold which you can purchase on amazon or at a local grocery store)

Unbox Small Parts And Tools

Locate tools and hardware for assembly

After removing the base, you can remove the top piece of foam to access the rest of the printer parts. The bottom part of the box includes the top frame of the printer, as well as the electronics box and a box of other parts. Remove the electronics box and set it aside for now.

Go ahead and open the part box now. There are several things in the box that you'll need for the rest of the assembly process. Creality includes a set of tools, so pull the bag of tools out and set them nearby. You will also find a bag of bolts and two brackets which will be used in the next step to assemble the printer frame.

Assemble The Printer Frame

Place lock washers on the bolts

Bolt the top frame to the printer base

It's time to attach the top frame to the printer base. This is where the printer will take shape!

First, pull the bolts out of the hardware bag. You should also have four lock washers in the bag, which you will need to slide onto the bolts. Then, you can pull the top frame out of the box. It will have several zip ties and pieces of shipping foam attached to it. You should cut the zip ties and remove the foam before attempting to assemble the printer.

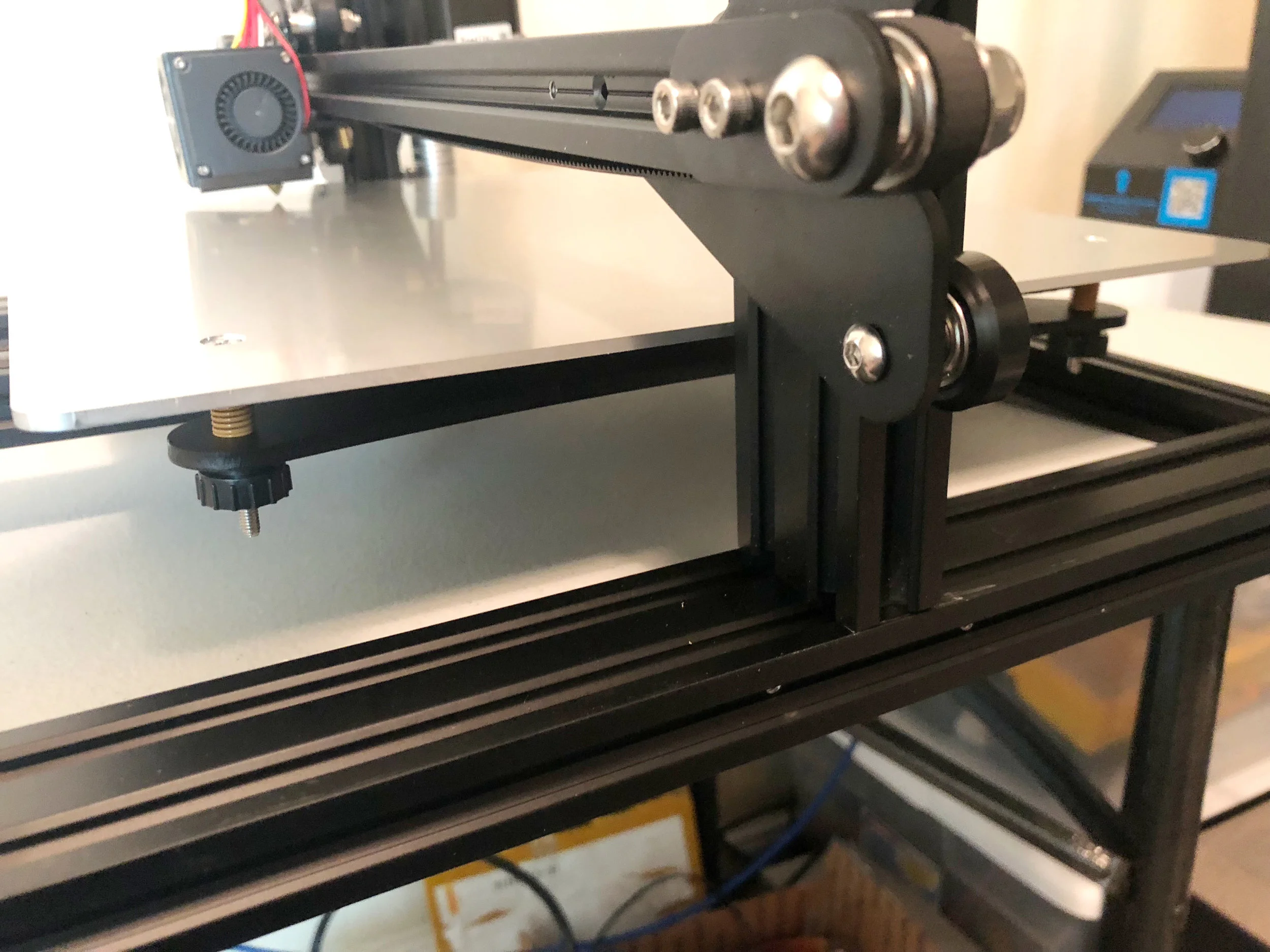

Next, you will need to line up the top frame with the base so you can bolt the two pieces together. The frame will be positioned so that the X motor on the frame is to the left when the printer is facing you (Y motor on the base is away from you). The frame is attached to the base with two bolts on each side. For each side, you will need to insert the bolts on the underside of the base and screw them in to the top frame.

We find it easiest to do this by placing the printer on the edge of a table with the edge of the base off the table so that I can easily insert the bolts. If you can find someone to help you with this part, they can hold the frame in place while you install the screws (don’t fully tighten them until all four have been partially inserted). It may take a few attempts to line up the top frame with the bolt holes, but you should be able to screw in the bolts successfully.

You will need to insert two bolts on each side of the printer. We recommend not fully tightening any of the bolts until you have partially inserted all four bolts. Once you have all of the bolts inserted, tighten them all completely.

Install Frame Brackets

Attach side brackets to the printer

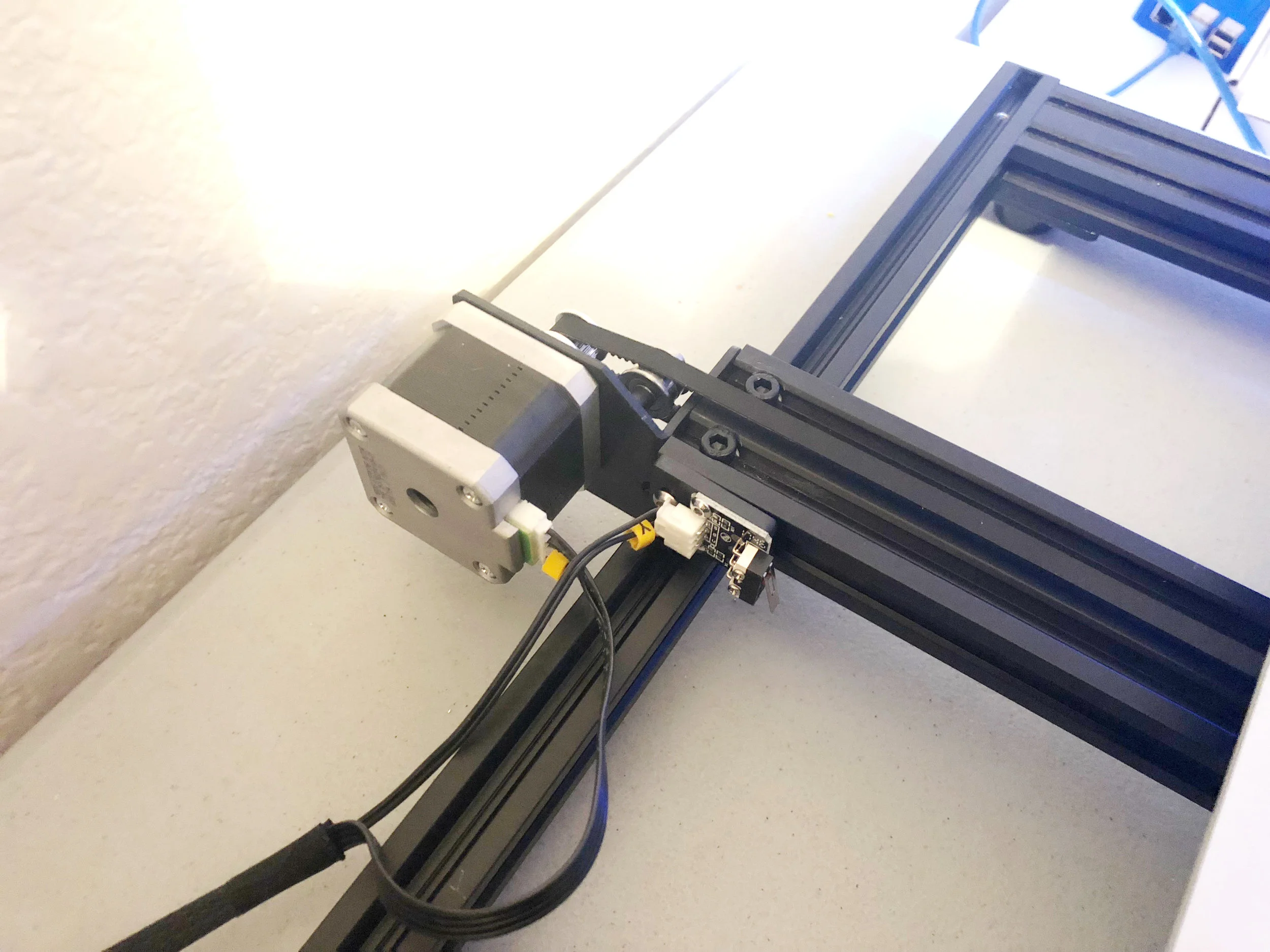

Ensure that the bracket with the Z endstop goes on the left side of the printer

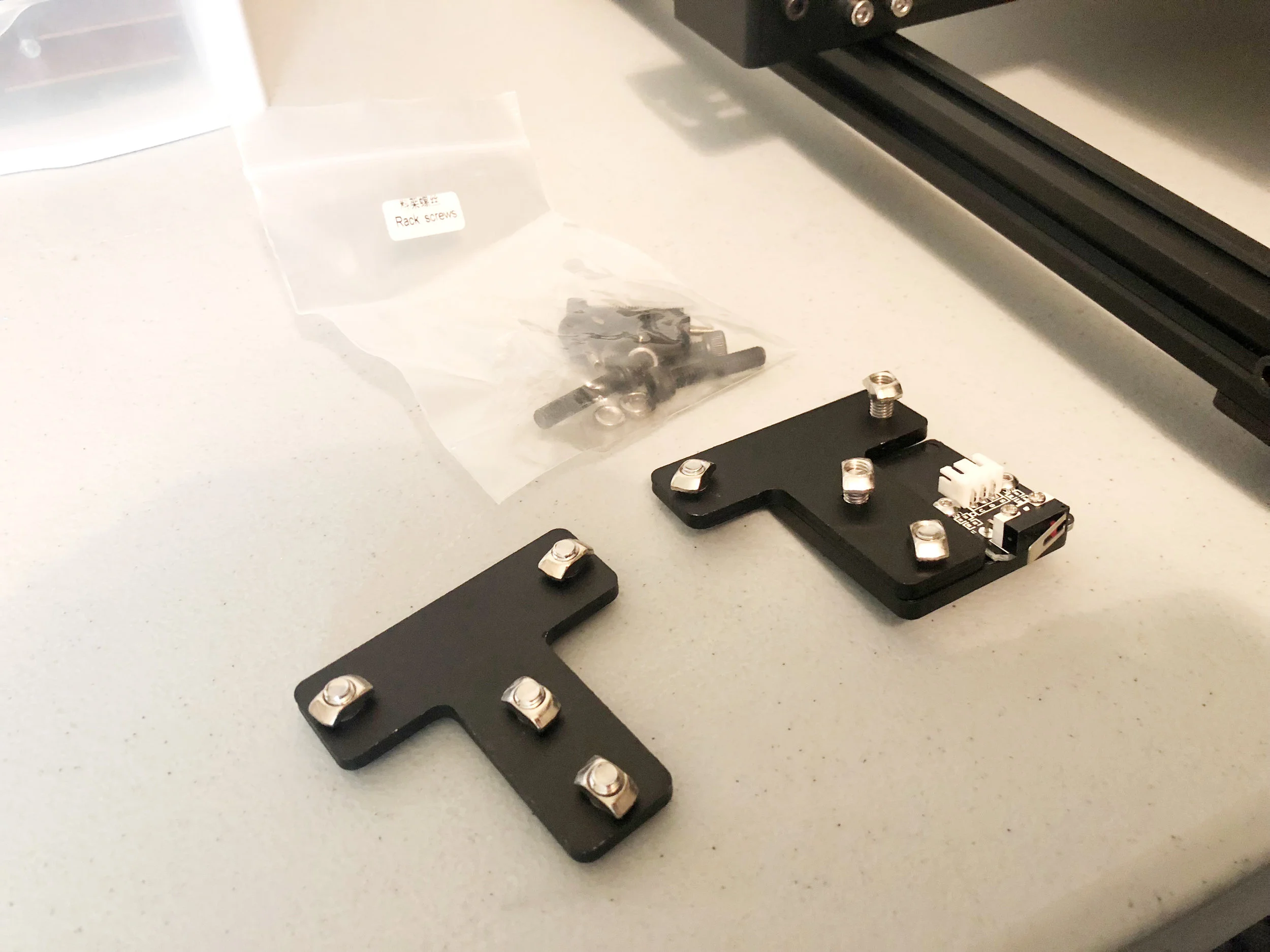

After bolting the frame together, you will need to attach the side brackets to the frame. This will further secure the frame to the base and ensure the printer remains rigid during operation.

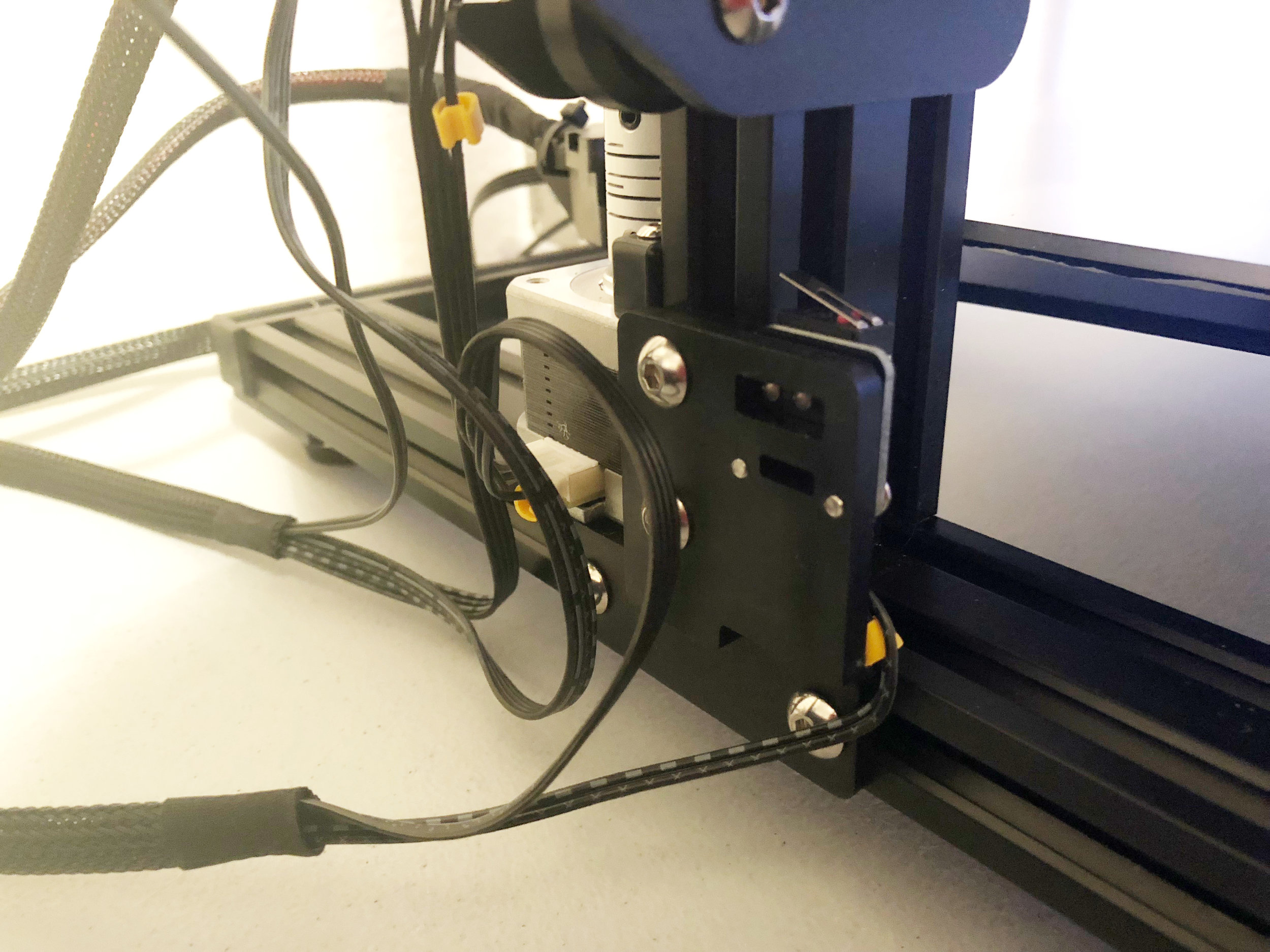

The two brackets are different, and it is important to put each one on the correct side of the printer. You will notice that one of the brackets has an electronic switch attached to it, which acts as an end stop to tell the printer when it has reached the lowest position on the Z axis. This bracket will go on the left side of the printer, close to the X and Z motors.

Each bracket has four bolts attached to it. Each bolt has a T-shaped nut on the end, which will fit into the channel on the aluminum extrusions of the frame. This allows the bracket to securely attach to the frame.

As you position the bracket on the printer, ensure that all four nuts are pressed into the channel on the aluminum extrusion. Then, tighten the bolts securely. Repeat this process for the other bracket.

Attach Bowden Tube To Extruder

Attach Bowden tube to the extruder

Clip the extruder power cable onto the extruder assembly

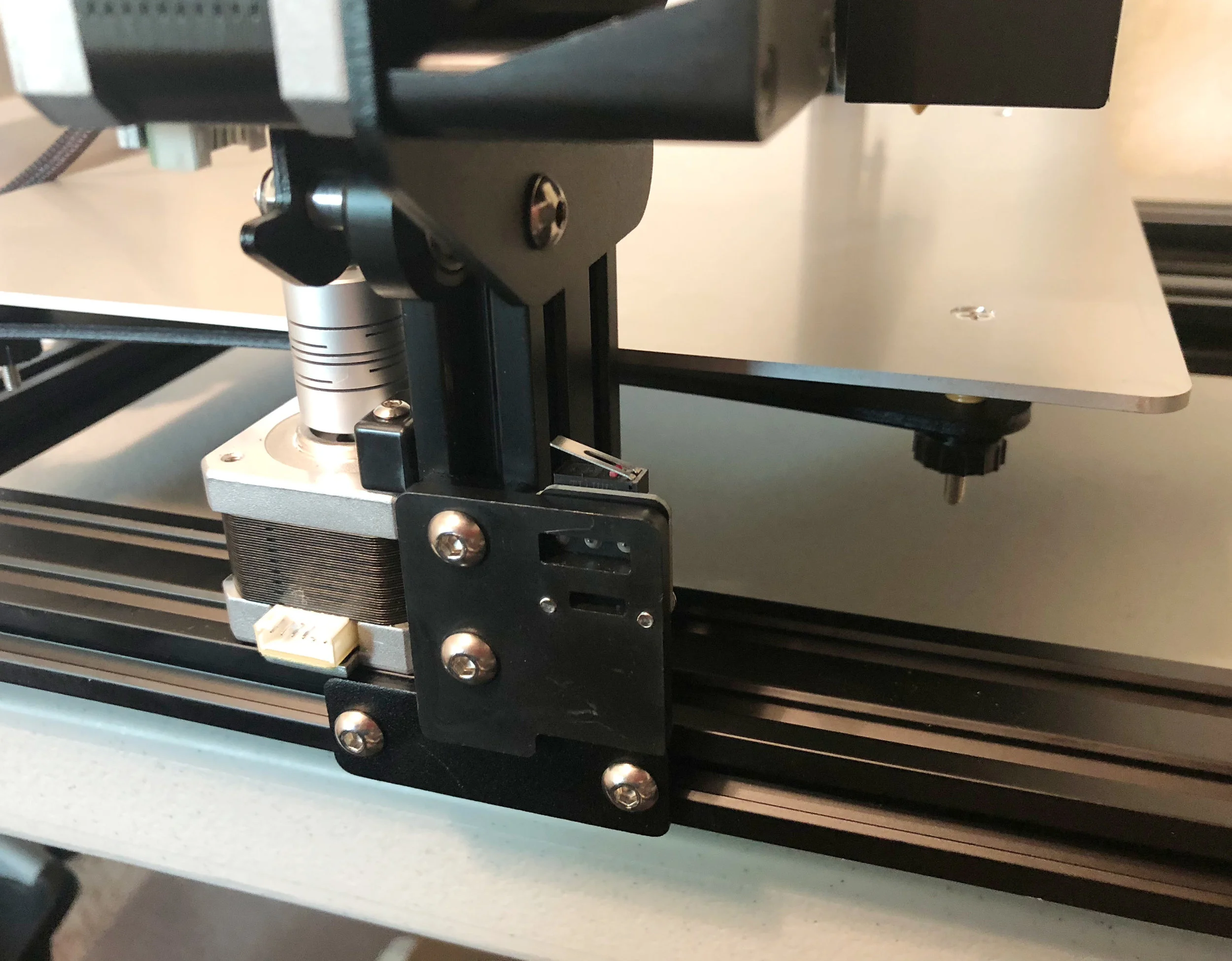

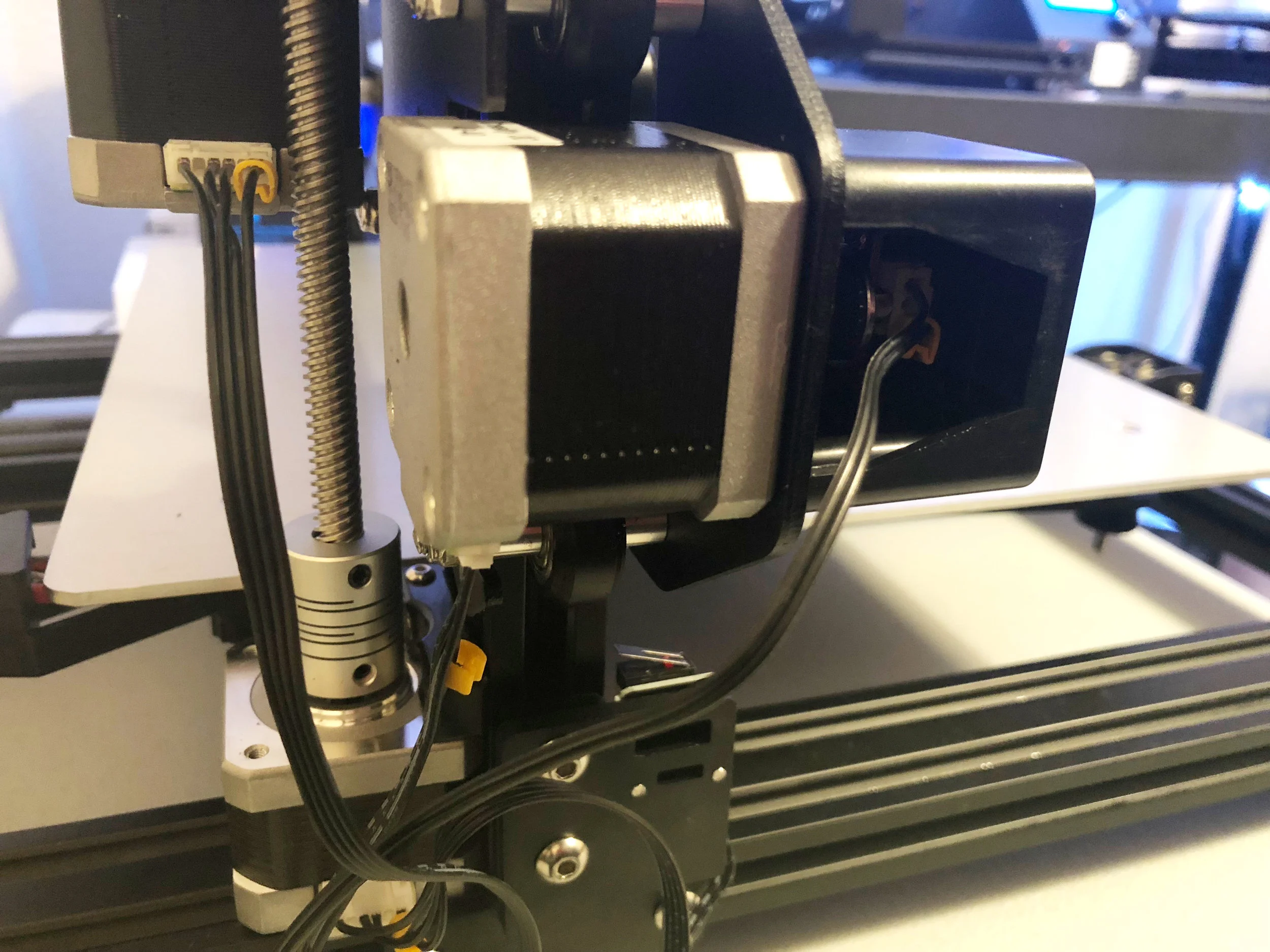

Once the printer frame is assembled, you will need to attach the Bowden tube to the extruder. The Bowden tube is the flexible white tube that guides the plastic filament from the extruder motor to the nozzle.

The Bowden tube comes attached to the nozzle, but is not attached to the extruder. To attach it, simply press the white tube into the small metal coupling on the extruder. Press the tube all the way into the coupling as far as it will go.

The Bowden tube also has a power cable attached to it. This cable supplies power to the heater on the nozzle in addition to carrying the signal for the thermistor on the nozzle. To keep this cable from getting in the way of the printer, you can press it into a clip on the back part of the extruder as seen in the image (note: newer models include an all metal Extruder, which does not have this clip).

Attach the Glass Bed

If you removed the glass bed at the beginning of assembly, you can now attach it using the four provided binder clips. Ensure that you place two clips at the front and two at the back. If the clips are on the side they will interfere with the movement of the print bed.

At this point, the printer is fully assembled! The only step left is to plug in the electronics.

Plugging In Electronics

Attach motor and endstop cables to their corresponding locations on the printer

Attach the heat bed and extruder cables to the electronics box

Plug the printer into wall power

To complete the printer assembly, you will need to plug in the electronics box. You will notice that the electronics box has several cables attached to it, as well as plugs on the back for the two cables already attached to the printer.

Each cable has a small plastic label on it, which indicates where it needs to be plugged in.

Note: You can purchase a set of extension cables on Amazon which allow you to store the printer controller further away from the printer. For example, mounting the control box underneath the table. These cables plug into the existing cables to extend them.

Installing the ‘X’ wires (top) and “Z” Wires (bottom) on the left side of the printer

X: Left side of the printer on the top frame, including the X motor and X endstop

Y: Back of the printer base, including the Y motor and Y endstop

Z: Left side of the printer on the printer base, including the Z motor and Z endstop

E (extruder): Left side of the printer on the top frame, for the extruder motor

Installing the “Y” wires to the rear of the printer

For the X, Y, and Z cables, you will see two plugs. The larger plug should be attached to the motor. The smaller plug should be attached to the endstop located near the motor. Note that the plugs will only fit into the connector one way, so be sure the plug is oriented correctly before inserting it.

Some of the endstop connectors are difficult to access due to their location on the printer, but you should be able to fit the plug into the connector for each motor and endstop.

Once you have attached the motor and endstop cables, you will need to attach two wires from the printer to the electronics box. These wires correspond to the heat bed and the extruder, and are attached to the circular connectors on the back of the electronics box.

Connecting the Electronics box wiring

Each circular connector will only fit one of the cables, and will only fit in one orientation, so it is easy to match up each cable with the correct connector. For each cable, plug it firmly into the connector and tighten the metal locking ring to secure the cable.

The only remaining connector is the power connector on the back of the electronics box. Before plugging power in, you should check on the right side of the electronics box for a small switch. This switch allows you to select between 110V and 220V power. Make sure you've selected the correct power setting for your region before plugging in power! (for USA, it is 110V)

Once you've confirmed the power setting, plug the power cable into the connector on the back of the printer, and then into wall power. At this point, you should be able to turn on the power switch on the back of the electronics box. You'll hear the extruder cooling fan spin up, and will see information on the LCD screen on the front of the electronics box.

Next Steps

You've completed the assembly process for your new printer! At this point, you're ready to perform a few basic calibration steps and do a test print!

Your best next step is to check out our guide on Bed leveling for Creality printers. We'll show you how to quickly get the bed adjusted for proper printing so you can start using your new printer.

We also recommend picking up a few spare parts that we always keep on hand to keep our printers up and running. Check out our repair parts guide for the full list of parts and why we like them.