Comparing the Prusa MK3S+ vs the Creality Ender 3 V2 Neo

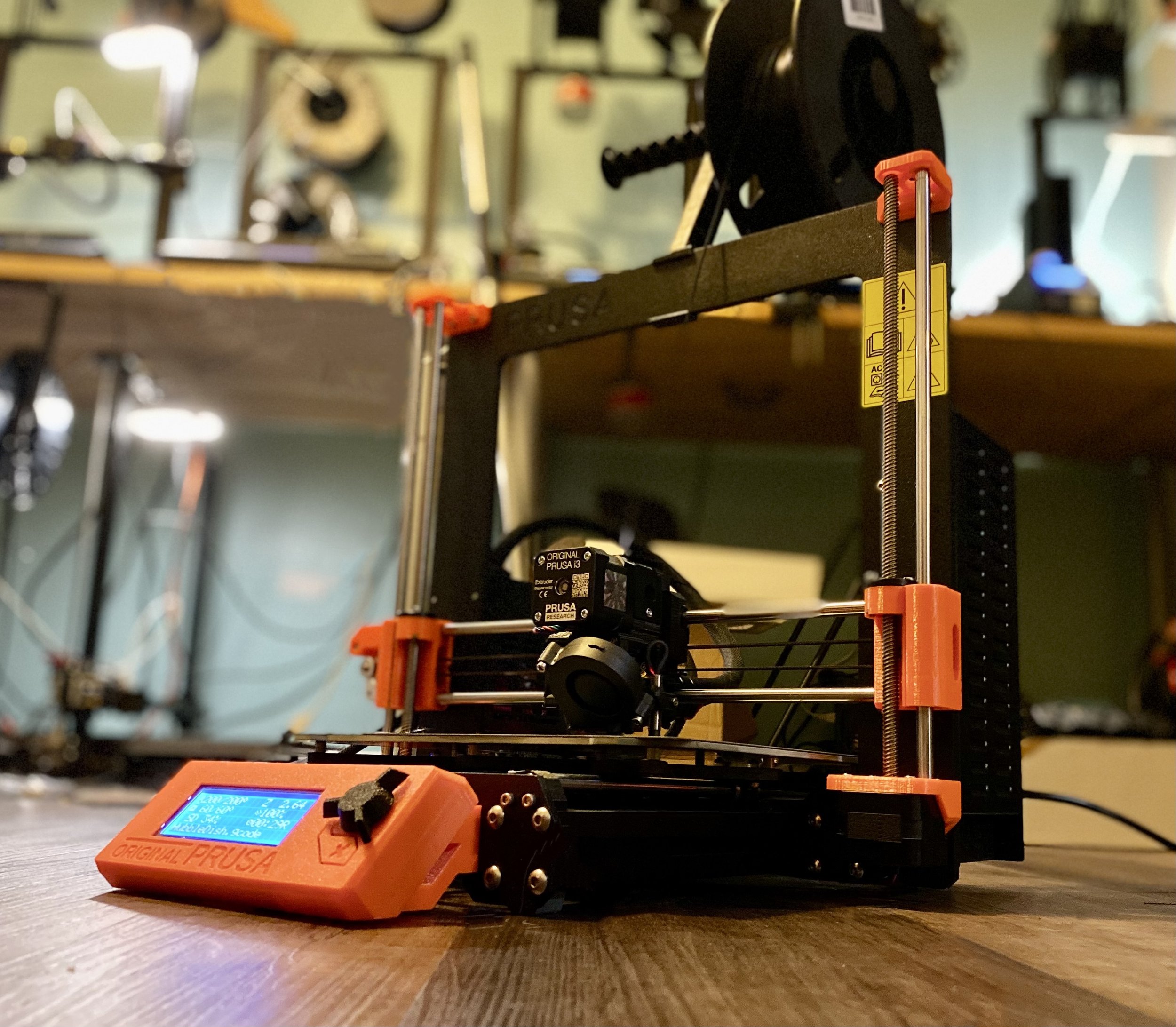

The Ender 3 V2 Neo and the Prusa MK3S+ are two popular 3D printers that cater to different segments of the market. The Ender 3 V2 Neo is a budget-friendly option from Creality that offers a solid set of features and good print quality, making it an excellent choice for beginners and those on a tight budget. On the other hand, the Prusa MK3S+ is a more expensive machine that promises better performance to match its higher price. Do you get what you pay for, or is the Ender 3 V2 Neo just as good?

While we are more familiar with Creality than Prusa, we wanted to see for ourselves how the Ender 3 V2 Neo compares to the Prusa MK3S+. To ensure an accurate and fair comparison, we purchased an assembled Prusa MK3S+ printer and put it through numerous test prints and orders for our 3D printing business. Based on our evaluation, we’ve created a detailed comparison of these two well-known 3D printers.

First, we'll examine the feature sets more closely, as there are more differences than might initially meet the eye. We'll also consider other factors that could influence your decision beyond the feature set. Finally, we'll offer our recommendations to help you determine which of these 3D printers would be the best choice for you.

Note: Creality Experts receives a commission for items you purchase from this page, at no additional cost to you. For more information, please see our affiliate link policy.

Vs.

Capability Comparison

Extruder

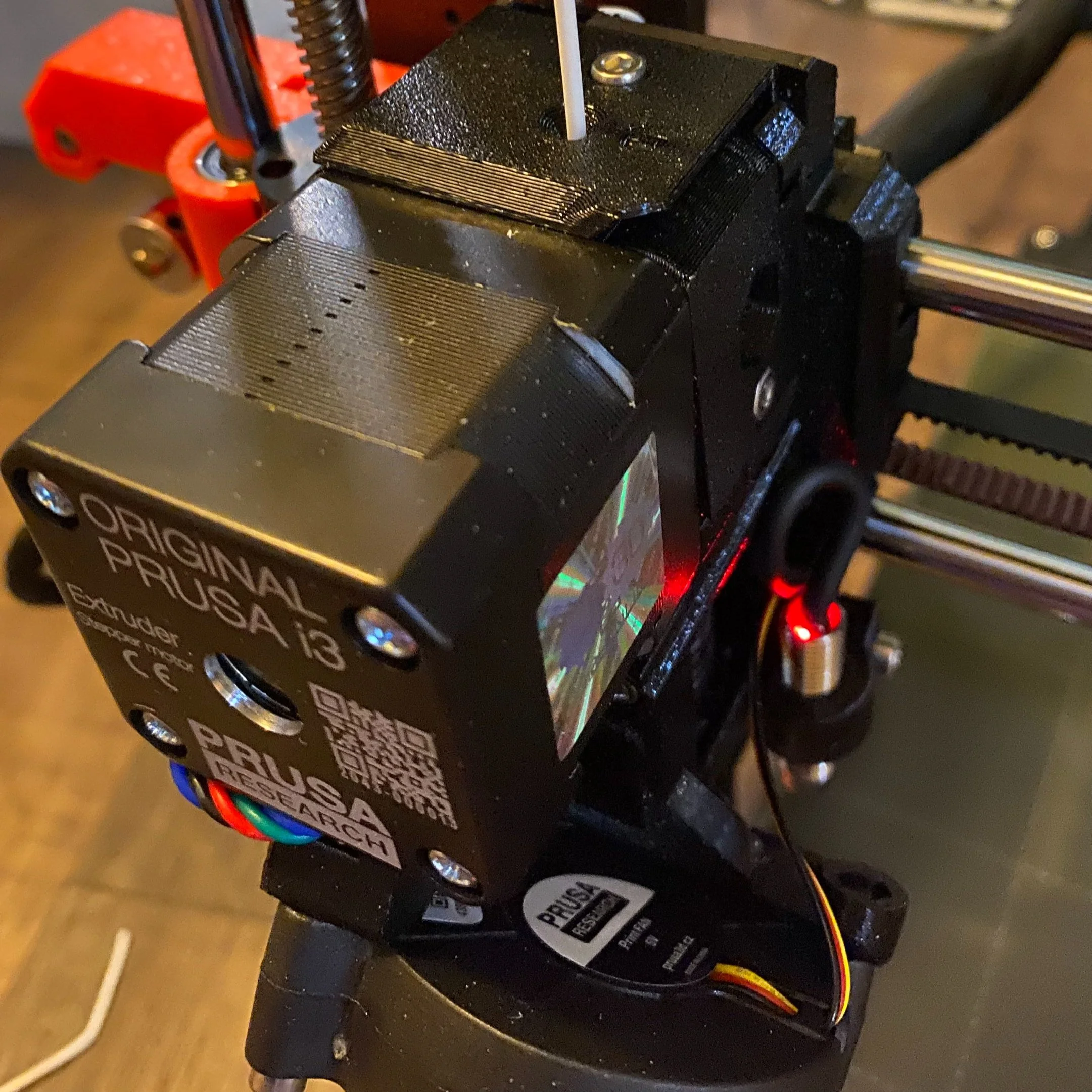

The Prusa MK3S+ direct drive extruder drives filament within the print head

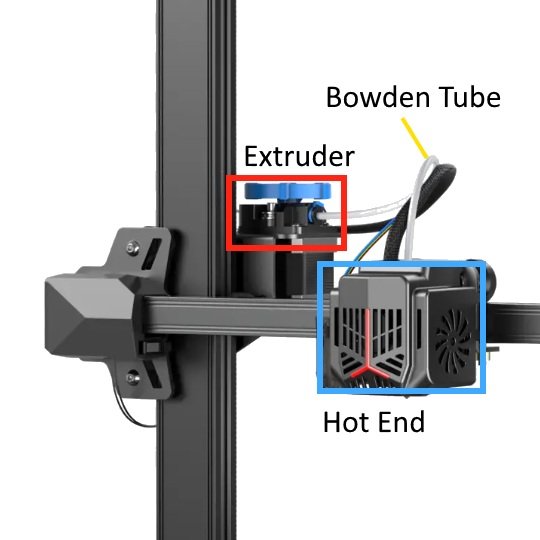

The Creality Ender 3 V2 Neo uses a Bowden-style extruder, which positions the extruder on the side of the printer rather than on the print head. On the other hand, the Prusa MK3S+ uses a direct drive extruder.

The extruder is the powered mechanism that feeds filament towards the hot end. In a Bowden-style extruder, the device is attached to one of the vertical side arms of the printer. The extruder feeds the filament through a flexible tube towards the hot end on the print head, resulting in a lighter moving print head. On the other hand, direct-drive extruder designs place the extruder on the print head, directly above the hot end. This allows the extruder to feed filament directly into the hot end without the need of the flexible tube. This design leads to a heavier print head due to the added motor and extruder assembly.

A direct drive extruder allows for better control and more precise printing, particularly with flexible filament materials such as TPU. Printers with Bowden extruders can print at fast speeds on standard filament types but require slower speeds on flexible filaments to reduce the chance of stringing and jams. In our experience, direct drive extruders also eliminate a common category of print failures by not requiring the flexible Bowden tube. We’ve found that over time, the tube can start to pull out from the hot end, which will eventually cause a jam even with standard PLA filament. Direct drive extruders are not as prone to causing this issue.

In this category, the Prusa MK3S+ has the edge over the Ender 3 V2 Neo. While we’ve run thousands of successful prints on Bowden extruder 3D printers, direct drive is undeniably better.

Hot End

The Prusa MK3S+ is equipped with an all-metal hot end, which provides significant advantages when it comes to printing at higher temperatures. This feature is particularly useful for users who want to print with more advanced and high-temperature materials, such as polycarbonate, nylon, and some types of PETG.

An all-metal hot end is designed to withstand high temperatures without degrading, as it does not rely on PTFE tubing inside the heat break. PTFE tubing, commonly found in other hot end designs including the one used on the Ender 3 V2 Neo, can begin to degrade when exposed to temperatures above 260°C. This increases the chance of jams or other printing failures. With an all-metal hot end, the Prusa MK3S+ can safely print at temperatures up to 300°C or higher, allowing you to safely print high-temperature materials with no increased risk of jams or other failures.

This high-temperature printing capability opens up a wider range of material options, allowing you to experiment with more advanced and specialized filaments that require higher temperatures to print properly. This feature contributes to the versatility and overall performance of the Prusa MK3S+, making it a valuable addition for users who require the flexibility to work with a variety of materials.

On the other hand, the hot end on the Creality Ender 3 V2 Neo is a standard PTFE-lined hot end, which shouldn’t be heated past 260°C. You’ll be able to print all standard filament types with this hot end, including PLA, ABS, most PETG, and TPU. And keep in mind that you do have the option to upgrade the hot end later—for example, you could install Creality’s Spider hot end on the Ender 3 V2 Neo.

Motion System

Both the Ender 3 V2 Neo and MK3S+ use a standard Cartesian motion system, where the bed moves back and forth in the Y axis as the print head moves left and right in the X axis and upward in the Z axis. This is the most common motion system for filament 3D printers, and we have no concerns about it for either printer.

The Ender 3 V2 Neo uses a set of rubber wheels on each axis, which grip the aluminum extrusions which make up the frame of the printer. This is a common design among Creality and 3D printers, and has no major issues. The Prusa MK3S+, on the other hand, uses linear rails to ensure all axes are very rigid. While there may not be a noticeable difference in print quality due to the linear rails, they are expected to require less maintenance over time compared to the pulley system on the Ender 3 V2 Neo. We don’t find ourselves needing to maintain this aspect of the motion system on our Creality 3D printers, so the decreased maintenance may be more of a theoretical benefit than a practical one.

We think this is a very minor difference between the machines, and not a notable difference to consider.

Bed Surface and Adhesion

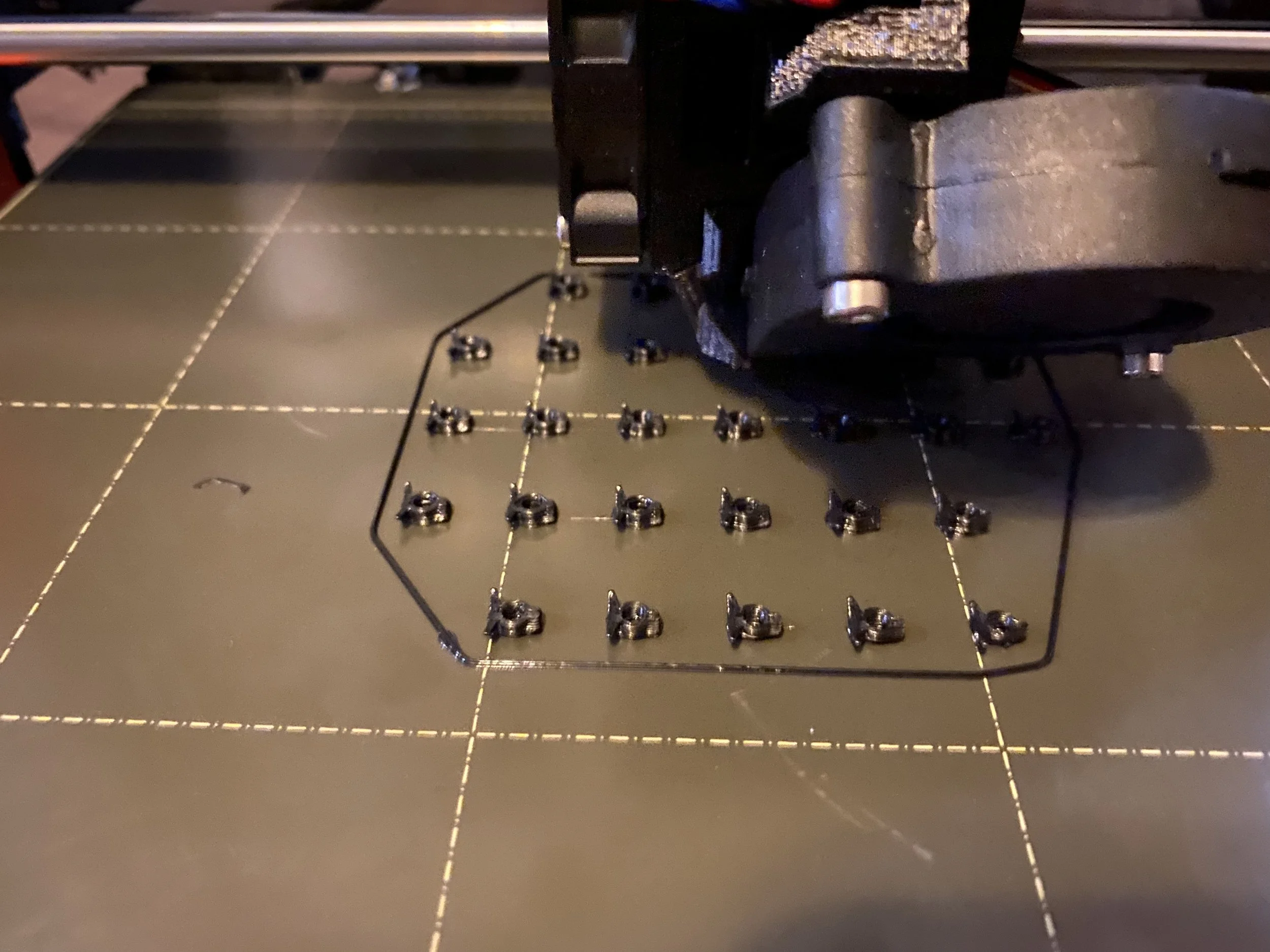

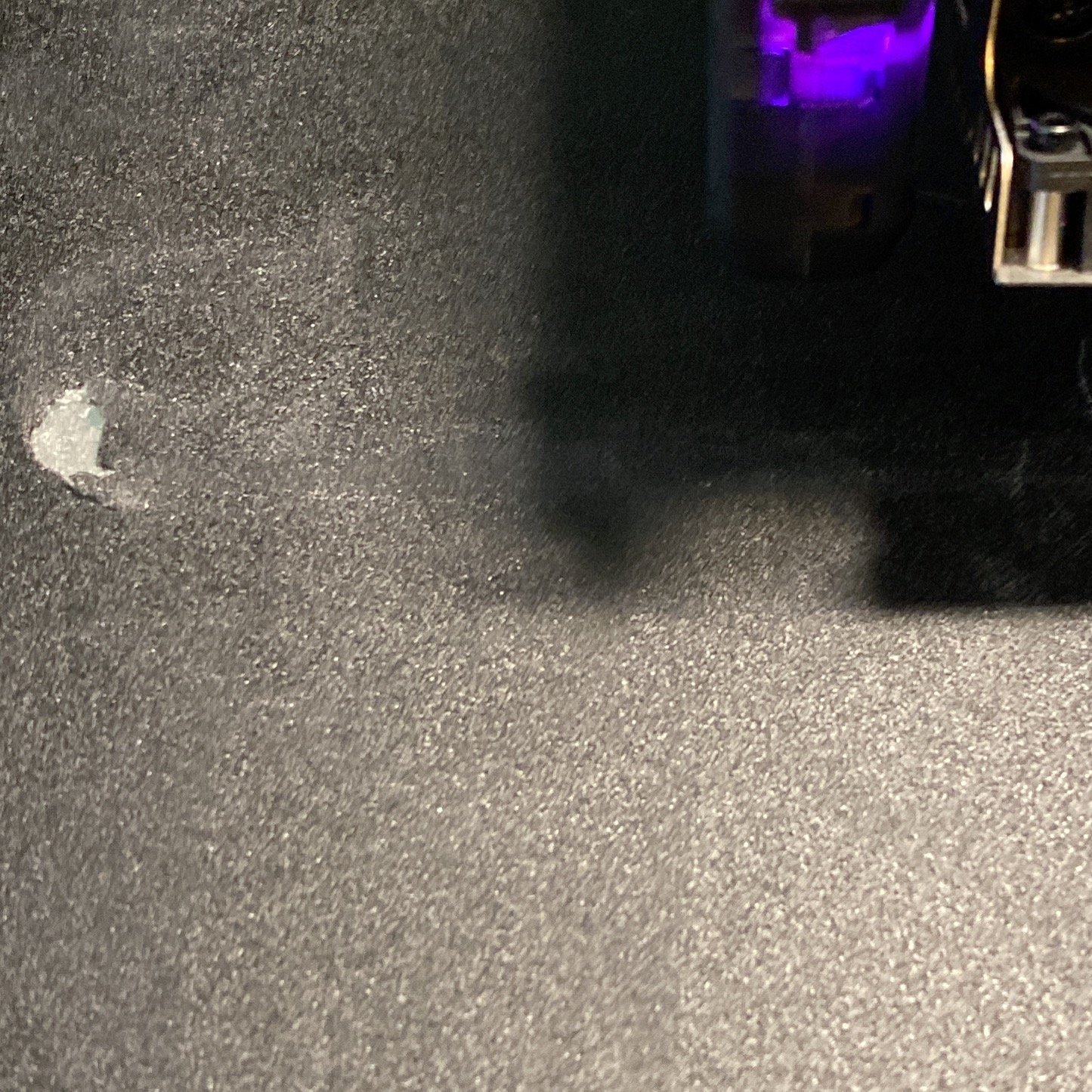

We were very happy with the adhesion of Prusa’s PEI bed; it is able to handle small parts without adhesion issues, but parts can be removed fairly easily once it cools.

The PC spring steel bed on the Ender 3 V2 Neo is prone to damage, which is exacerbated by the fact that parts stick very well to the bed, even after it cools.

The Prusa MK3S+ features a PEI spring steel bed, while the Creality Ender 3 V2 Neo comes with a PC spring steel bed. Between these, the bed on the Ender 3 V2 Neo makes removing completed prints more challenging. Printed parts adhere to the bed very well, so you may need to use a scraper to pry the parts off, but you have to be cautious to not gouge the PC surface of the bed. You can upgrade the Ender 3 V2 Neo’s bed easily to match the Prusa bed (see our guide for recommended upgrade options) but out of the box, it’s not the best bed material.

In contrast, the PEI bed on the Prusa MK3S+ makes it easy to remove prints without much force, and it can handle small parts without unnecessary adhesion to the bed. What makes this material better is that parts tend to pop off the bed once it cools down, so it’s often possible to remove prints without using a scraper or any other tool.

Comparing the bed materials, the Prusa MK3S+ is definitely better out of the box, but upgrading the Creality Ender 3 V2 Neo's bed is a simple process if you choose to do so later.

Both the Prusa MK3S+ and the Ender 3 V2 Neo have heated beds that can reach up to 110°C, which is sufficient for printing all standard 3D printing filament.

User Interface and Controls

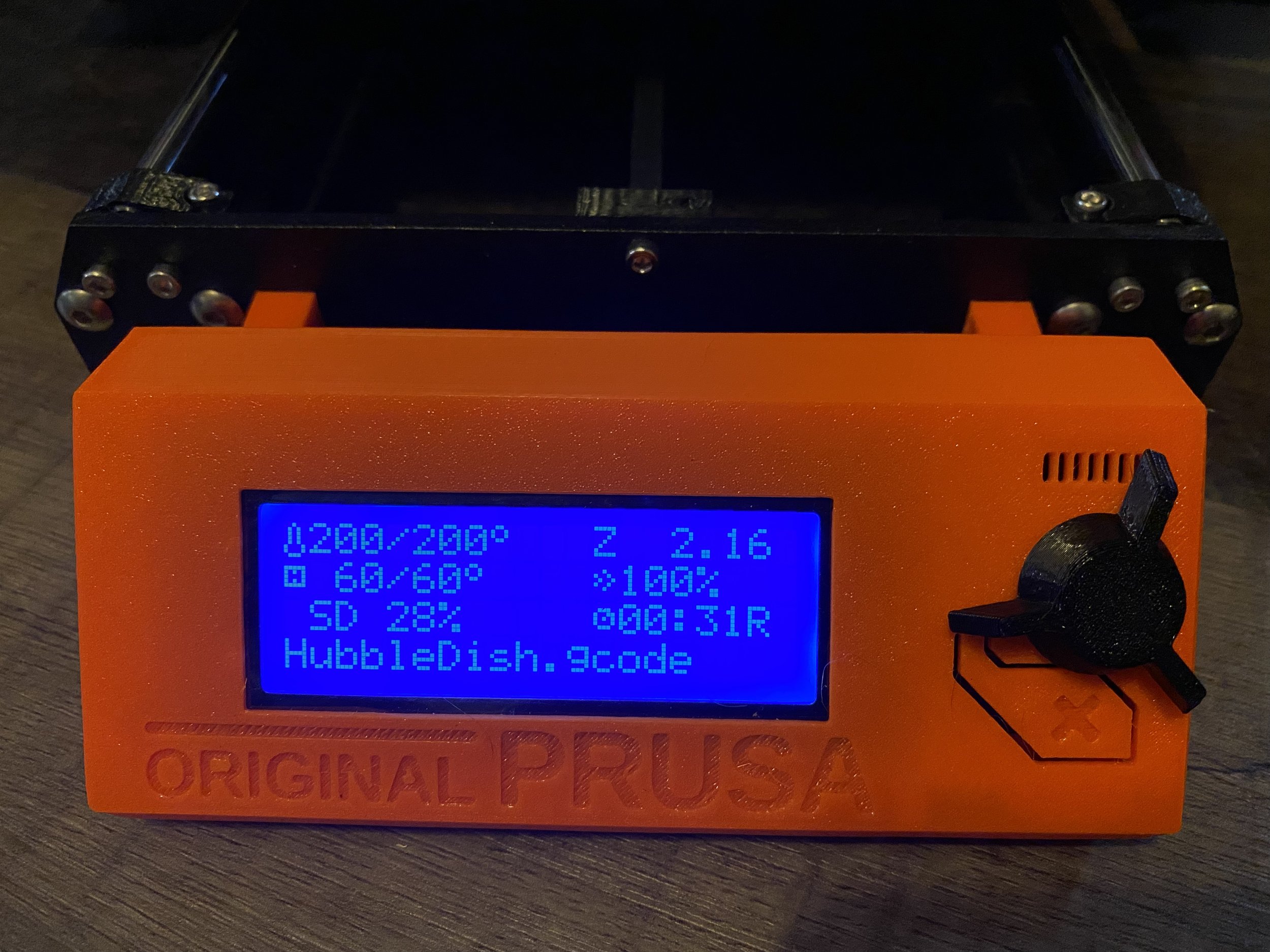

The Prusa MK3S+ has a simple 4-line monochrome LCD screen that provides limited capabilities, but is well-designed and does not detract from the overall printing experience. The Creality Ender 3 V2 Neo, on the other hand, uses a more visually appealing graphical interface, which feels more modern and allows for faster navigation. Both user interfaces achieve the goal of allowing you to operate the printer, but the Ender 3 V2 Neo definitely wins here.

The screen of the Prusa MK3S+ is limited, but the UI design and attention to detail make it easy to work with.

In contrast, the Creality Ender 3 V2 Neo has a graphical LCD, which is easier to navigate and more pleasant to look at.

Build Volume

The Ender 3 V2 Neo offers a slightly larger build volume compared to the Prusa MK3S+, with a build area of 220 x 220 x 250 mm compared to the MK3S+'s 210 x 210 x 250 mm. This is a minor difference in size, and shouldn’t be too much of a deciding factor unless you are printing objects that push the build volume to its limit.

Print Quality

Both the Creality Ender 3 V2 Neo and the Prusa MK3S+ deliver great print quality out of the box, which is typical of most modern 3D printers. However, the Prusa MK3S+ does have a few advantages that could lead to improved print quality.

The Prusa MK3S+ is equipped with a larger blower-style fan for part cooling, which significantly enhances the quality of overhangs. It demonstrates superior performance in handling steep overhangs, producing clean and sharp edges even at challenging angles. 3D printed parts often include overhangs, and the improved cooling will result in a better quality print. The Ender 3 V2 Neo offers satisfactory overhang performance, but it doesn't quite match the exceptional quality achieved by the Prusa MK3S+. While it can handle steep overhangs to a certain extent, the results may not be as crisp and clean as those produced by the Prusa printer.

Additionally, the linear rail system on the Prusa MK3S+ mentioned previously may result in slightly cleaner prints, but we didn’t notice a meaningful difference in our testing.

Assembly and Ease of Use

The assembly process for these two 3D printers differs in a few ways.

The Creality Ender 3 V2 Neo ships as a partially assembled kit. The assembly process is fairly straightforward, and there are many tutorials and guides available online to assist. We consider this to be a fairly easy assembly process—Creality has made the assembly simpler than it was for previous Ender 3 printers, and most users should be able to assemble the printer very easily.

The Prusa MK3S+ is available as either a kit or fully assembled. The fully assembled option is self-explanatory, and although you pay more for it, the printer is ready-to-go out of the box. On the other hand, the kit option requires significantly more time and effort to assemble as compared to the Ender 3 V2 Neo—about 8 hours typically. It does save some money over the fully-assembled version, and it can be a valuable learning experience if you want to understand the ins and outs of your 3D printer to make maintenance and upgrades easier later.

Both 3D printers have a relatively straightforward calibration process, with the Ender 3 V2 Neo featuring a BL-touch sensor for automatic bed leveling, while the Prusa MK3S+ uses a mesh bed leveling system. Both systems make it easy for users to ensure proper bed leveling before each print. Even with a kit, you should be able to calibrate either printer easily and get printing.

Brand Differences

Creality 3D printers are manufactured in China, whereas Prusa Research operates out of the Czech Republic. Owing to the lower labor costs and easier access to components, Chinese-made 3D printers are more affordable to produce, thus allowing for a more competitive price point. Furthermore, the Prusa MK3S+ incorporates 3D printed components in its assembly. This affords Prusa several benefits, such as rapid iteration for part updates, as well as the opportunity to thoroughly test their printers during the production of these components. However, large-scale 3D printing is generally more costly than conventional manufacturing methods, like injection molding.

When it comes to non-3D printed parts, Prusa emphasizes component quality, with cost being a secondary concern. For instance, Prusa employs high-grade parts for its linear rail system, as well as renowned Bondtech and E3D components for the extruder and hot end. Creality, conversely, adopts a more balanced strategy with the Ender 3 S1 Pro by manufacturing certain parts in-house, such as the CR-touch leveling sensor and a Creality-branded power supply. Creality has traditionally prioritized cost, but their higher-end models like the Ender 3 S1 Pro demonstrate a commendable equilibrium between quality and cost-effectiveness.

Quality Control

It becomes evident as soon as you unbox the MK3S+ that Prusa invests significantly in testing and quality control. With our assembled unit, we received a checklist and test results sheet, demonstrating all the evaluations performed before shipping. Moreover, the printer arrived with a finished test print on the bed, indicating that Prusa runs an actual print test on every unit they manufacture. In contrast, Creality printers do not undergo such rigorous testing, and sometimes minor issues that require adjustments arise. From our experience purchasing over 30 Creality printers at retail, we've observed minor QC issues in 10-15% of the machines, but didn’t encounter any showstopper issues that prevented us from using the printers effectively.

Enhanced quality control comes at a cost, and it is likely a contributing factor to the higher price point of Prusa's products. Ultimately, if you're willing to pay more for a machine that will almost certainly work flawlessly right out of the box, the Prusa MK3S+ is better suited to your preferences.

Customer Support

Creality, the manufacturer of the Ender 3 V2 Neo, has a mixed reputation for customer support. They offer support through their website and social media channels, but users may experience varying degrees of responsiveness and assistance.

Prusa, on the other hand, is known for its excellent customer support, offering responsive assistance via live chat, email, and phone. They also maintain an active and supportive community where users can ask questions and share their experiences. The Prusa support team is committed to helping customers troubleshoot issues and get the most out of their 3D printers.

Price

One of the largest differences between these printers is in their price and shipping.

The Creality Ender 3 V2 Neo comes in at around $300-$325, and can sometimes be found cheaper on sale. Like other Creality printers, it is available at many 3D printer resellers in addition to Amazon.com. You’ll be able to order the printer and receive it fairly quickly—in as little as two days with Amazon Prime’s free shipping. You can view current pricing for the Creality Ender 3 V2 Neo here.

The Prusa MK3S+ costs around $650 for the unassembled kit version, or $900 for the assembled version. Shipping is an extra cost, and comes in as high as $100 for the assembled version (although the kit version has cheaper shipping due to fitting into a smaller box). You may have to wait a few weeks for for the printer to ship, and the shipping itself will take a week or two since the printers are shipped from Prusa’s offices in the Czech Republic. You can view current pricing and lead times for the Prusa MK3S+ here.

As you can see, the cost and shipping time for these two printers is quite different. The Prusa MK3S+ is comparatively expensive and may take a while to get to you, whereas the Creality Ender 3 V2 Neo is available for immediate shipping at a much lower price.

The Verdict

Before we give our recommendations, here’s a full recap of the printers to summarize:

When deciding between the Creality Ender 3 V2 Neo and the Prusa MK3S+, you’ll need to consider your budget, printing needs, and the level of support you require. The Ender 3 V2 Neo is an excellent option for those on a tight budget or beginners who are just getting started with 3D printing. It offers good print quality, a solid set of features, and the potential for upgrades to improve its performance over time. We think this is a solid machine that will perform well, and it offers an excellent value for the price.

The Prusa MK3S+, while more expensive, delivers exceptional print quality, robust construction, and excellent customer support. It is an ideal choice for users who demand the best print quality with consistent, reliable results, or users who prefer the safety net of Prusa’s well-regarded customer support.

Both the Ender 3 V2 Neo and the Prusa MK3S+ have their merits, and the choice comes down to your individual priorities, budget, and preferences. By carefully considering these factors, you can choose the right 3D printer to suit your needs and enjoy the rewarding world of 3D printing.

If you’d like to compare other printers, take a look at our 3D Printer Comparison Tool. This tool lets you view multiple 3D printers side by side to easily compare features.